With the growth of E-Commerce, its easier for everyone to buy almost anything from anywhere in the world. And all the physical products move around the world in the Corrugated Shipping Boxes. I am going to help you choose the right Corrugated box for your product.

Understanding Corrugated Boxes

Updated On: Nov. 26, 2019

The good old Corrugated box is what keeps the product safe. Whether its the Laptop or the body lotion, everything is shipped in the Corrugated boxes.

What are the Corrugated Boxes?

The corrugated box is made by sandwiching the wave-patterned sheet between two layers of paper. The Wave like sheet stuffed between the paper is known as the Flute.

The Flute is what keeps the product inside the Carton box Safe from any mishandling. The Flute absorbs most of the shock pressure caused due to rough handling of the box.

Corrugation & Raw Material

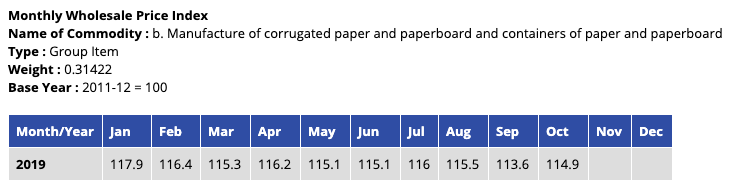

The image above shows the Monthy Wholesale Price Index (WPI) of the corrugated paper board. Since I am writing the post in November, we'll assume the WPI for December is 114.9 (same as October)

If we have WPI for the beginning and end of the year, the inflation rate of the commodity "Manufacture of corrugated paper and paperboard and containers of paper and paperboard" for the year 2019 will be,

(WPI of end of the year – WPI of the beginning of the year)/WPI of the beginning of year x 100

(114.9 - 117.9 )/117.9 x 100 = -2.5%

It represents Deflation, where the inflation rate falls below 0%. Its a healthy sign for the corrugation industry.

As per IPMA, the Kraft Paper/Board industry is growing at 8.88%, with the domestic market size of 5.67 Million Tons.

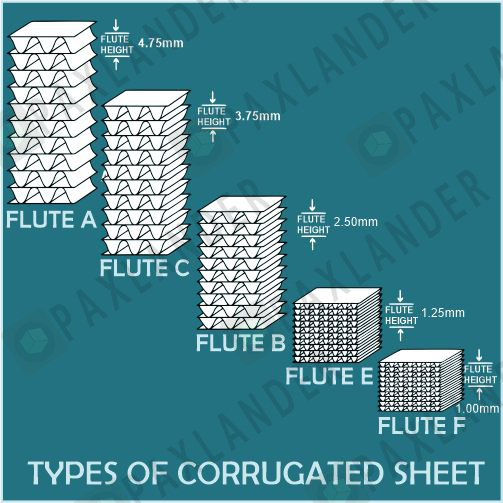

What are the types of fluting?

The Flute is the wave-like kraft sheet sandwiched between the two layers of paper. The Flute is very important in a corrugated box as it provides the cushioning & safety to the product packed inside. Let's discuss the type of Flutes commonly used in the market.

A-Flute: A-Flute has about 30-36 flutes per 30cm, which is the biggest among all other types of flutes available.

B-Flute: B flute provides the second-highest arch size at about 44-50 flutes per 30cm. It has good stacking strength and crushing resistance.

C-Flute: The C flute is an all-purpose flute that has about 36-42 flutes per 30cm. The C-Flute has the larger Flute as compared to the B-Flute but has the same weight as the B-Flute.

E-Flute: E flutes are an environmentally friendly substitute for green packaging, which has about 86-94 flutes per 30cm. Its used making boxes for retail packaging, printed corrugated box packaging.

F-Flute: F-Flute has 124-132 flutes per 30cm and is the cheapest among all. The F-Flute box has low cushioning and shouldn't be used to pack delicate items but will work to make E-Commerce boxes and food delivery boxes.

Depending on the requirement, the different Flutes are combined to provide safety. For example, the combination of Flutes A & B offers better cushioning and rigidity.

Growth of Consumer Durables & E-Commerce

As per IBEF, the e-commerce industry is forecasted to reach 64 Billion by 2020. Consumer Durables Report 2019, Indian appliance and consumer electronics is expected to increase at a 9% CAGR to reach Rs 3.15 trillion (US$ 48.37 billion) in 2022. By FY22, the television industry in India is estimated to reach Rs 1,227.34 billion (US$ 17.56 billion).

Demand growth is likely to accelerate with rising disposable incomes and easy access to credit.

All consumer durables need reliable, carton box packaging, which means the growing demand for the corrugated boxes.

With the rising competition & demand, the distance between the seller and the buyer doesn't matter much. The ordered item might make multiple hops before its delivered to the buyer. Its apparent the demand for reliable biodegradable Corrugated boxes will increase.

Why is Paper Quality important?

The quality of the paper used to manufacture the Carton boxes depends on the GSM & the Burst Factor measurement of the Paper.

Initially, the paper is selected for the box, which is then used to make the Corrugated sheet. The Corrugated sheet is further used to manufacture Carton boxes.

Its obvious the paper with the higher GSM & BF will have the better strength than the paper with the lower values. So you can decide based on the product to be packed inside the box. If the product to be packed is delicate and fragile, then you can go with the higher GSM & BF. The paper with low GSM & BF can be used to manufacture Food delivery boxes.

Why do Carton Boxes have different Flute combination?

Depending on the requirement, different or the same Flute can be combined to provide better strength or cushioning or both. If you know the Shipping box will be used to pack and ship glass products, then the combination of BC Flute is used to make the boxes.

The manufacturer can make any combination of Flute depending on the requirement and paper raw material available.

What is the Golden Brown Paper?

As the name suggests, the golden brown paper has the golden texture to it and looks better than the regular brown paper. The paper is slightly expensive but gives the premium feel to the customer. The printing over the golden brown paper looks good too.

Using the golden brown paper doesn't necessarily mean the paper has better strength than the natural brown paper.

What are the factors which help in determining the Paper quality to be used for manufacturing?

The factors such as the weight of the product to be packed inside the box, the number of boxes to be stacked over each other, how the boxes will be delivered to the customer are used to determine the quality of the paper.

If the Corrugated Shipping box is used to pack and deliver fragile items, then the Paper quality should be higher.

If the budget is low, then instead of going with the Paper of higher GSM and BF, the medium quality paper can be used in combination with Flutes. For example - It might be possible the Corrugated box with lower quality paper might be better in combination with B & E Flute while the box with the higher grade Paper.

Usually, the manufacturer decides the box attribute based on the requirement in hand as he/she seems fit.

Now you have the appropriate knowledge to decide the right Packaging box for your product. You can compare quotations from different vendors and suppliers based on quality measurements such as GSM, BF, and Flute.

Branded Corrugated Box

The corrugated box can be printed with your print design. The minimum order quantity for logo printed Carton Box starts from 2,000 pieces.

If you don't have the printing design ready, then I'll recommend ordering your customized box online. After placing the order, you can ask for the available themes and select one of them. You'll get the whole design ready within two days.

If the company has its packaging designer, then its the designer's responsibility to add extra details to the print design.

Let's discuss some of the details except the logo, which should be kept in mind while preparing the box design.

- Brand Tagline

- Veg or Non-Veg checkbox

- Store address & contact details

- Social media handles

- Message to the customer

- Ventilation holes ( optional )

Its essential for the packaging design to understand how many colour can be used and the type of box ordered.

The outer layer of the carton box can be white or golden brown. There's a restriction on the number of colour which can be printed on the brown corrugated box. Some of the standard colour used in the corrugated box design are Black, Red, Green, Brown

Brown Vs. White Carton Boxes

White corrugated paperboard is prepared by pasting the white sheet on top of the brown corrugated paper. In the small factories its done manually by hand, and in the large factories, the process is automated.

The Whiteboard provide the consistent background for printing. The golden-brown board is fine for an extreme colour like black, red but its not suitable for the mild pastel colours.

The printing will be darker on the brown corrugated box, and its difficult to print different shade of the same colour as red and light red. And printing over the whiteboard appears to be truer and brighter.

The box is handled and moved countless times, and every time it gets slightly dirty. The white box tends to get dirty quickly and spoils the branding. On the other hand, the brown box looks the same and doesn't give the apparent impression of the rough handling which most boxes go through while shipping.

The white corrugated box isn't considered as green. The white paper is generally the bleached virgin paper and not the recycled paper. The virgin paper is the fresh paper made from wood. So if you're marketing 100% recycled box somewhere on the box, it might not be true.